“Lean Project Management: Streamlining Processes for Value Delivery” explores how Lean principles can be applied to project management to eliminate waste, optimize resources, and focus on delivering maximum value to stakeholders. The article highlights key Lean tools and techniques, such as value stream mapping, continuous improvement, and minimizing non-essential tasks, to improve efficiency and project outcomes. It emphasizes a value-driven approach, helping teams achieve faster delivery, higher quality, and better resource utilization.

Introduction to Lean Project Management

Imagine a world where projects run smoothly, delivering exactly what stakeholders need, without any waste. That’s the promise of lean project management. This innovative approach zeroes in on value delivery while trimming away inefficiencies.

In today’s fast-paced environment, adopting lean principles is crucial. It ensures that resources are used optimally, and projects meet ever-changing demands. By focusing on what’s essential, project teams can achieve more with less.

The benefits of lean approaches are undeniable. Faster delivery times, improved quality, and enhanced team collaboration are just a few. Embracing lean project management not only streamlines processes but also paves the way for sustainable success.

Understanding Lean Principles

Value

At the heart of lean is the concept of value. In project management, this means understanding what truly matters to stakeholders and focusing efforts on delivering those elements.

Value Stream

The value stream represents all the steps required to deliver a project. By mapping it out, teams can identify and eliminate inefficiencies, ensuring resources are channeled toward value-generating activities.

Flow

Flow ensures that tasks progress smoothly without interruptions. In project management, maintaining flow means removing bottlenecks and enabling team members to work efficiently and effectively.

Pull

The principle of pull involves producing work based on demand. This approach helps manage resources wisely and reduces waste, aligning project outputs with current needs.

Perfection

Finally, perfection is an ongoing pursuit in lean project management. It encourages continuous improvement, where teams consistently refine processes to enhance quality and value delivery.

By weaving these principles into project management, teams can streamline their processes, focusing on delivering maximum value with minimal waste.

Key Lean Tools for Project Management

In the realm of lean project management, several tools stand out for their effectiveness in reducing waste and optimizing processes. These tools help teams streamline their workflows and focus on delivering value.

Value Stream Mapping

Value stream mapping is a visual tool that illustrates the flow of materials and information through the project lifecycle. By mapping out each step, teams can identify bottlenecks and areas of waste. For example, in a software development project, it can highlight delays in coding or testing phases, prompting targeted improvements.

Kanban

Kanban is a method that visualizes task progress on boards, allowing teams to manage work efficiently. By limiting work in progress, it prevents overloading team members and ensures a steady flow of tasks. A marketing team might use Kanban to track campaign development stages, ensuring tasks move smoothly from planning to execution.

5S

5S stands for Sort, Set in order, Shine, Standardize, and Sustain. This tool helps in organizing the workspace to enhance efficiency and reduce waste. In a manufacturing context, 5S can be used to organize tools and materials, making them easily accessible and reducing time spent searching for items.

By employing these tools, projects can achieve greater efficiency and value delivery, aligning closely with lean principles.

The Role of Continuous Improvement

Imagine you’re trying to improve your morning routine to save time. You start by making small tweaks, like preparing your outfit the night before. This is the essence of Kaizen in lean project management, which emphasizes small, continuous improvements for lasting results.

Kaizen, a Japanese term meaning “change for the better,” is a core principle in lean methodology. It encourages teams to consistently evaluate their processes, looking for incremental changes that can enhance efficiency and value delivery.

But how do you know if these small changes are making a difference? That’s where iterative processes and feedback loops come into play. By regularly reviewing results and gathering feedback, teams can adapt and refine their approaches. This cycle of iteration ensures that improvements are not only implemented but also effective.

Isn’t it amazing how a simple concept like Kaizen can transform a project’s trajectory? By embracing continuous improvement, teams not only streamline processes but also foster a culture of innovation and adaptability, ultimately leading to more successful project outcomes.

Minimizing Non-Essential Tasks

Picture a team working tirelessly on a project, only to find themselves bogged down by tasks that add little to no value. Non-essential tasks can act like anchors, slowing down project momentum and diverting valuable resources away from critical objectives. In the world of lean project management, identifying and eliminating these tasks is key to boosting efficiency and productivity.

Take, for instance, a marketing team drowning in endless meetings that rarely lead to actionable outcomes. By recognizing this as a form of waste, the team can reclaim hours each week. So, what strategies can help identify and cut out such waste?

- Conduct regular audits of current processes to pinpoint tasks that do not contribute to project goals.

- Implement the “Five Whys” technique to dig deeper into why a task exists and whether it is truly necessary.

- Encourage team members to voice concerns about tasks they find redundant or unproductive.

- Leverage technology for automation of repetitive, time-consuming activities.

By focusing on what truly matters, teams not only enhance their efficiency but also create more space for activities that drive genuine value and innovation.

Delivering Maximum Value

In project management, value is the ultimate measure of success. It’s not just about completing tasks but ensuring those tasks meet the needs and expectations of stakeholders. Value is defined by the benefits and outcomes that stakeholders receive from a project, aligning closely with their goals and objectives.

To truly deliver value, aligning project goals with stakeholder needs is crucial. This ensures that every step taken in the project lifecycle contributes to achieving desired outcomes. A clear comparison between traditional and lean project management approaches highlights this focus:

| Traditional Project Management | Lean Project Management |

|---|---|

| Focuses on adhering to predefined plans. | Emphasizes adaptability and stakeholder feedback. |

| Project goals often set without stakeholder input. | Continuous alignment with stakeholder needs. |

| Efficiency driven by rigid processes. | Efficiency driven by value-centric processes. |

- Lean approaches encourage ongoing communication with stakeholders to ensure alignment.

- Flexibility in lean methodologies allows for adjustments based on stakeholder feedback.

Ultimately, lean project management prioritizes delivering what matters most to stakeholders, ensuring projects are not only completed efficiently but also with maximum impact.

Case Study: Lean Project Management in Action

Background

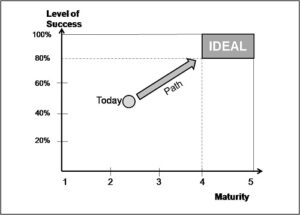

In the bustling world of software development, TechInnovate, a mid-sized company, embarked on a mission to streamline its product release cycle. The team had struggled with lengthy timelines and resource bottlenecks, prompting them to adopt lean project management principles for their next big project.

Challenges

Initially, the team faced resistance to change. Long-standing processes were deeply ingrained, and shifting to a lean mindset required a cultural overhaul. Additionally, identifying real value from stakeholder perspectives proved challenging, as priorities varied widely.

Solutions

TechInnovate embraced tools like value stream mapping to visualize and eliminate wasteful processes. They implemented regular Kaizen meetings to foster continuous improvement and established a clear feedback loop with stakeholders to refine and align project goals consistently.

Outcomes

The results were transformative. The project timeline was reduced by 30%, allowing faster delivery of high-quality software. Team morale improved as they witnessed their contributions directly impacting customer satisfaction. Ultimately, TechInnovate not only met but exceeded stakeholder expectations, cementing lean project management as a cornerstone of their operations.

FAQ: Lean Project Management

What is Lean Project Management?

Lean project management is a methodology focused on delivering maximum value by eliminating waste and optimizing resources. It aims to enhance efficiency and project outcomes.

How does lean differ from traditional project management?

Unlike traditional approaches that may focus on rigid schedules and processes, lean emphasizes flexibility, continuous improvement, and a deep understanding of value from the stakeholder’s perspective.

Are lean principles only applicable to manufacturing?

No, lean principles can be applied to various industries, including software development, healthcare, and service sectors. The focus is on improving processes and outcomes, regardless of the industry.

What are common misconceptions about lean?

A common misconception is that lean is only about cost-cutting. In reality, it’s about creating more value with fewer resources. Another misconception is that lean is rigid, but it actually encourages adaptability and continuous improvement.

How can a team start implementing lean principles?

Begin by identifying key processes and analyzing them for waste. Use tools like value stream mapping and Kanban to visualize workflows and enhance efficiency. Encourage a culture of continuous feedback and improvement.

Conclusion

In this article, we’ve explored how Lean Project Management serves as a powerful approach to streamline processes and deliver maximum value. By focusing on key lean principles like value, flow, and continuous improvement, teams can effectively eliminate waste and optimize resources. Tools such as value stream mapping and Kanban play a crucial role in enhancing efficiency and project outcomes.

Adopting lean methodologies not only accelerates delivery and improves quality but also aligns project goals with stakeholder needs, fostering a more responsive and agile environment. As you consider your next project, we encourage you to explore these lean principles and tools to drive success and innovation. Lean into the possibilities and transform the way you manage projects for the better.

Must-Reads to Deepen Your Knowledge

THOMPSON, ERIC; Lean Project Management: This Book Includes: All You Need to know about Six Sigma, Scrum, Agile Project Management, Kanban and Kaizen to Become a Master of The PMP World Kindle Edition. 2020.

SZABO K.; Project Management Masterclass: A Practical Guide for Managing Waterfall, Agile, and Hybrid projects. 2024.